Today we will introduce the wet scrubber system used to treat the exhaust gas of the pepper drying workshop.

Pepper drying is a common practice in many regions of the world to preserve and enhance the flavor of pepper. However, the process of drying pepper can result in the emission of pungent odors that can be a nuisance for workers and the environment.

The pungent odor in pepper drying workshops is mainly due to the release of volatile organic compounds (VOCs) such as terpenes, which are responsible for the characteristic aroma of peppers. Therefore, it is essential to implement an effective purification method to control and eliminate the pungent odor in pepper drying workshops. One of the most effective methods is the use of wet scrubbers, which are devices that remove pollutants from a gas stream by passing it through a liquid medium. In this article, we will discuss the wet scrubber system in detail and its application for purifying the pungent odor in pepper drying workshops.

Overview of Wet Scrubber System

A wet scrubber is a device that removes pollutants from a gas stream by passing it through a liquid medium. The liquid medium can be water or a chemical solution, depending on the type of pollutant being removed. Wet scrubbers are widely used in various industries, including chemical, pharmaceutical, and food processing, to control air pollution. The basic principle of a wet scrubber is to use the liquid medium to trap and absorb the pollutants present in the gas stream. The scrubbed gas then passes through a mist eliminator to remove any remaining droplets of liquid before it is discharged into the atmosphere.

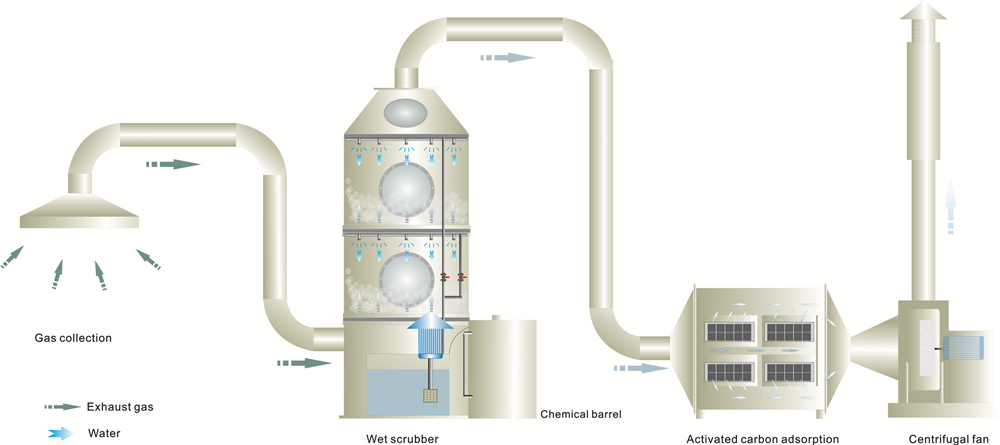

The wet scrubber system consists of several components, including the scrubber vessel, liquid circulation system, mist eliminator, fan, and ductwork. The scrubber vessel is the main component of the system, which contains the liquid medium and the scrubbing mechanism. The liquid circulation system pumps the liquid medium from the scrubber vessel to the top of the scrubber, where it is sprayed onto the gas stream. The mist eliminator removes any droplets of liquid from the scrubbed gas, and the fan pulls the gas through the scrubber vessel and the mist eliminator. The ductwork connects the scrubber vessel to the source of the gas stream and the outlet where the scrubbed gas is discharged into the atmosphere.

Application of Wet Scrubber System in Pepper Drying Workshop

The wet scrubber system is an effective method for removing pungent odors from the pepper drying workshop. The system works by capturing the VOCs released during the drying process and neutralizing them with a liquid medium. The liquid medium used in the wet scrubber system can be water or a chemical solution, depending on the type and concentration of the VOCs.

The following are the steps involved in the wet scrubber system for purifying the pungent odor in the pepper drying workshop.

Step 1: Design the Wet Scrubber System

The first step in implementing a wet scrubber system in the pepper drying workshop is to design the system. The design of the system depends on the type and concentration of the VOCs, the airflow rate, and the size of the workshop. The system should be designed to capture and neutralize the VOCs effectively and efficiently. The design of the system should also take into account the environmental regulations and the safety of the workers.

Step 2: Install the Wet Scrubber System

The next step is to install the wet scrubber system in the pepper drying workshop. The installation process involves setting up the scrubber vessel, the liquid circulation system, the mist eliminator, the fan, and the ductwork. The system should be installed by a qualified technician to ensure that it is done correctly.

Step 3: Operate the Wet Scrubber System

- Choose the location: Identify the location where the wet scrubber system will be installed. The location should be accessible for maintenance and should have sufficient space to accommodate the scrubber and its associated components.

- Prepare the foundation: Once the location is identified, prepare a solid and level foundation for the scrubber system. The foundation should be able to support the weight of the system and prevent any movement during operation.

- Install the ductwork: Install the ductwork that will connect the wet scrubber system to the process equipment generating the pollutant. Ensure that the ductwork is sized correctly to provide adequate airflow and that it is properly sealed to prevent any leakage.

- Install the scrubber system: Install the wet scrubber system on the foundation, ensuring that all components are securely fastened. Connect the ductwork to the inlet of the scrubber system.

- Install the pumps and piping: Install the pumps and piping required for the scrubbing solution. Ensure that the piping is correctly sized and routed to provide adequate flow to the scrubber.

- Connect the electrical components: Connect the electrical components of the wet scrubber system, including the motors, controls, and instrumentation.

- Test the system: Before commissioning the system, test it to ensure that all components are functioning properly. Perform a dry run to check the operation of the scrubber and mist eliminator, and a wet run to check the operation of the pumps and piping.

- Commission the system: Once the system has been tested and any necessary adjustments have been made, commission the system by starting it up and monitoring its performance. Make any necessary adjustments to ensure that the system is operating within design specifications.